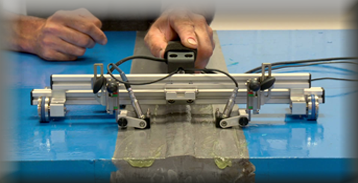

TIME OF FLIGHT DIFFRACTION TECHNIQUE(TOFD)

Time of flight diffraction is an advanced non-destructive testing method used for weld inspection. Time of flight diffraction (TOFD) is one of the most reliable non-destructive testing methods in testing welds for both pre-service and in-service inspection.

PHASED ARRAY ULTRASONIC TESTING (PAUT)

A certain number of industries requiring advanced means of Non-Destructive Testing, such as the nuclear, aeronautic or in-line testing industries, constantly seek improvements in the performance of their monitoring systems.

ULTRASONIC TESTING

Ultrasonic testing (UT) is carried out for evaluating the internal soundness of many engineering products made of steels and other metals and nonmetals processed through Casting, forging, rolling, extrusion, drawing and other modern processing techniques.

MAGNETIC PARTICLE TESTING

Magnetic particle testing (MT) is a non-destructive testing technique utilized to detect defects or discontinuities (such as cracks) at or near the surface in ferromagnetic metals such as iron, steel, nickel, cobalt, etc.

DYE PENETRANT TESTING

Liquid penetrant processes are non-destructive testing methods for detecting discontinuities that are open to surface. They may be effectively used in the inspection of both ferrous and non-ferrous metals and on non-porous, non-metallic materials, such as ceramics, plastics and glass.

RADIOGRAPHY INSPECTIONS

Industrial radiography is a method of non-destructive testing where many types of manufactured components can be examined to verify the internal structure and integrity of the specimen.

VISUAL TESTING

VT inspections may be by Direct Viewing, using line-of sight vision, or may be enhanced with the use of optical instruments such as magnifying glasses, mirrors, boroscopes, charge-coupled devices (CCDs) and computer-assisted viewing systems (Remote Viewing).

HARDNESS TESTING

A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing.

PMI ( POSITIVE METAL IDENTIFICATION)

PMI (Positive Material Identification) testing is the analysis of materials to determine the chemical composition of a metal or alloy at particular (usually multiple) steps of alloy manufacturing or in-process alloy installation.