Ultrasonic TestingRT

Ultrasonic inspection is a non-destructive method by which high frequency sound waves

are introduced into the object being inspected. Most ultrasonic inspection is done at frequencies between

0.5 and 20MHz.

The sound waves travel through the material with some loss of energy (attenuation) due to material characteristics.

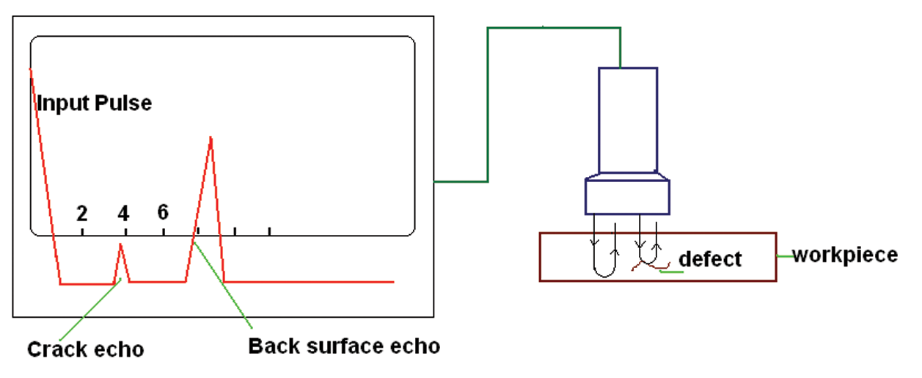

The intensity of sound waves is either measured, after reflection (pulse echo) at interfaces (or flaw) or is measured at the opposite surface of the specimen (pulse transmission).

The ultrasonic testing method is:

a) Used for detection of flaws in materials and for thickness measurement.

b) Used for the determination of mechanical properties and grain structure of material.

Categories

- Visual testing (VT)

- Liquid Penetrant Testing (LPT)

- Magnetic particle testing (MPT)

- Eddy current testing (ET)

- Radiographic testing method (RT)

- Ultrasonic testing (UT)

- Phased Array Ultrasonic Testing (PAUT)

- Time of Flight Diffraction (TOFD)

- Positive Material Identification (PMI)

- Hardness Testing (HT)

- Vacuum Box Testing (VB)

- Low Frequency Electromagnetic Technique (LFET)